- Eco-friendly packaging made from 100% post-consumer reclaimed fiber

- Can be recycled again

- Meets ASTM D 6868 composting standards

- Comfortable to grip, easy to pour

- Does not shatter

Packaging The Earth Can Live With

Ecologic is a hybrid paper packaging technology that leverages a strong fiber outer shell and a very thin inner plastic liner, resulting in containers that are up to 70% less plastic when compared to formats of the same size. The fiber outer shell, made of recycled cardboard and newspaper, provides structural stability and protection of the product inside. The inner liner, made of 80% recycled HDPE, keeps the product sanitary and clean. Together, the two pieces remain 100% recyclable (in their own streams) and help reduce consumer reliance on single-use plastics.

PRODUCT DESIGN

OUTER SHELL

High Performance with Strong Fiber

INNER LINER

Maximum Barrier with Minimal Plastic

- Made of up to 70% less plastic than rigid plastic bottles of the same size

- Recyclable, non-laminated, mono-polymer, #1 PET

- Produces low volume waste

- BPA-free

HOW IT'S MADE

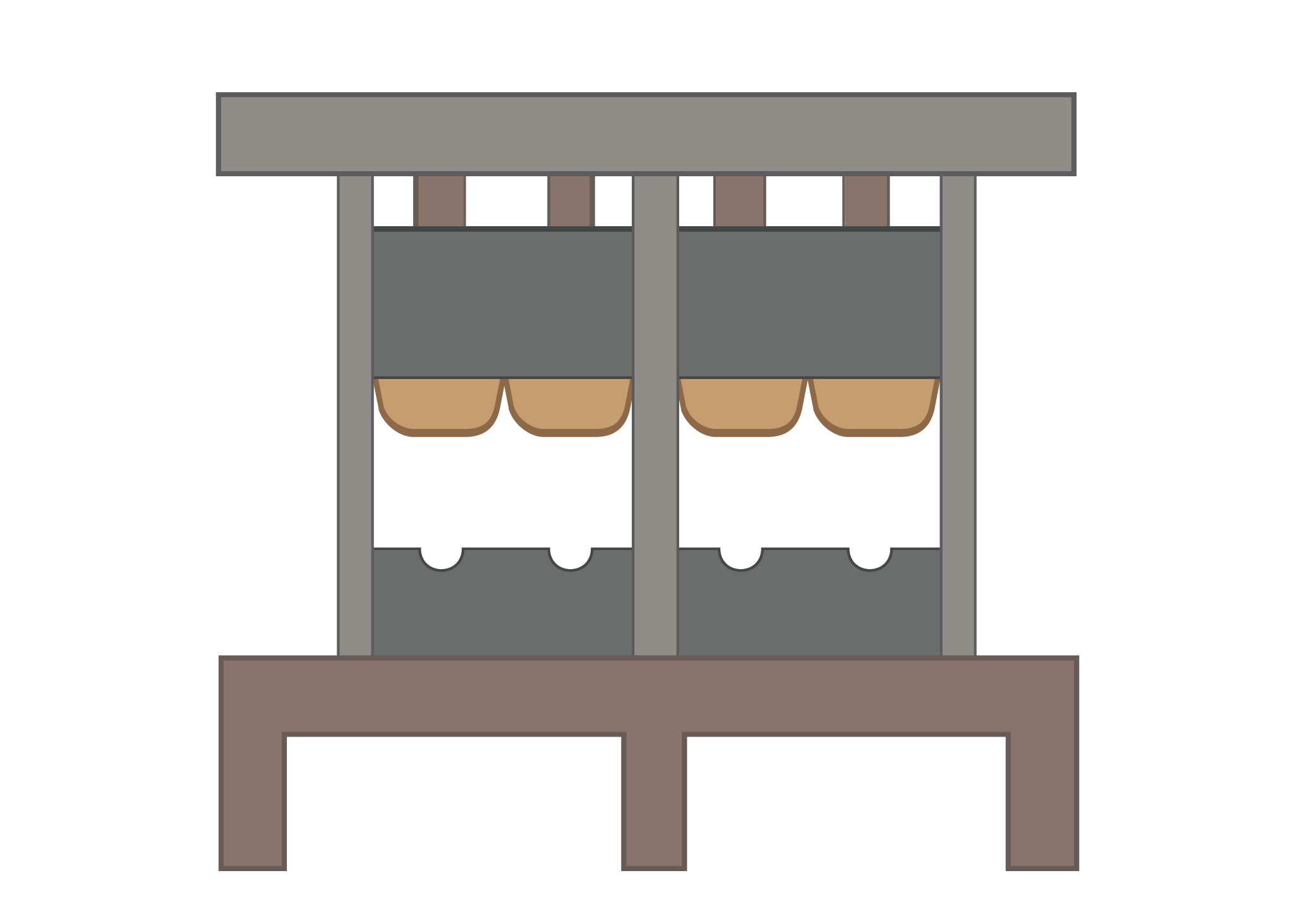

MOLDED FIBER

Ecologic utilizes world class molded fiber technology to produce fiber shells sturdy enough to withstand supply chain.

Post-consumer reclaimed fiber are made into a slurry mix that is transferred to a forming station, which applies tremendous heat and pressure onto tooling cavities that form hybrid paper bottle outer shells.

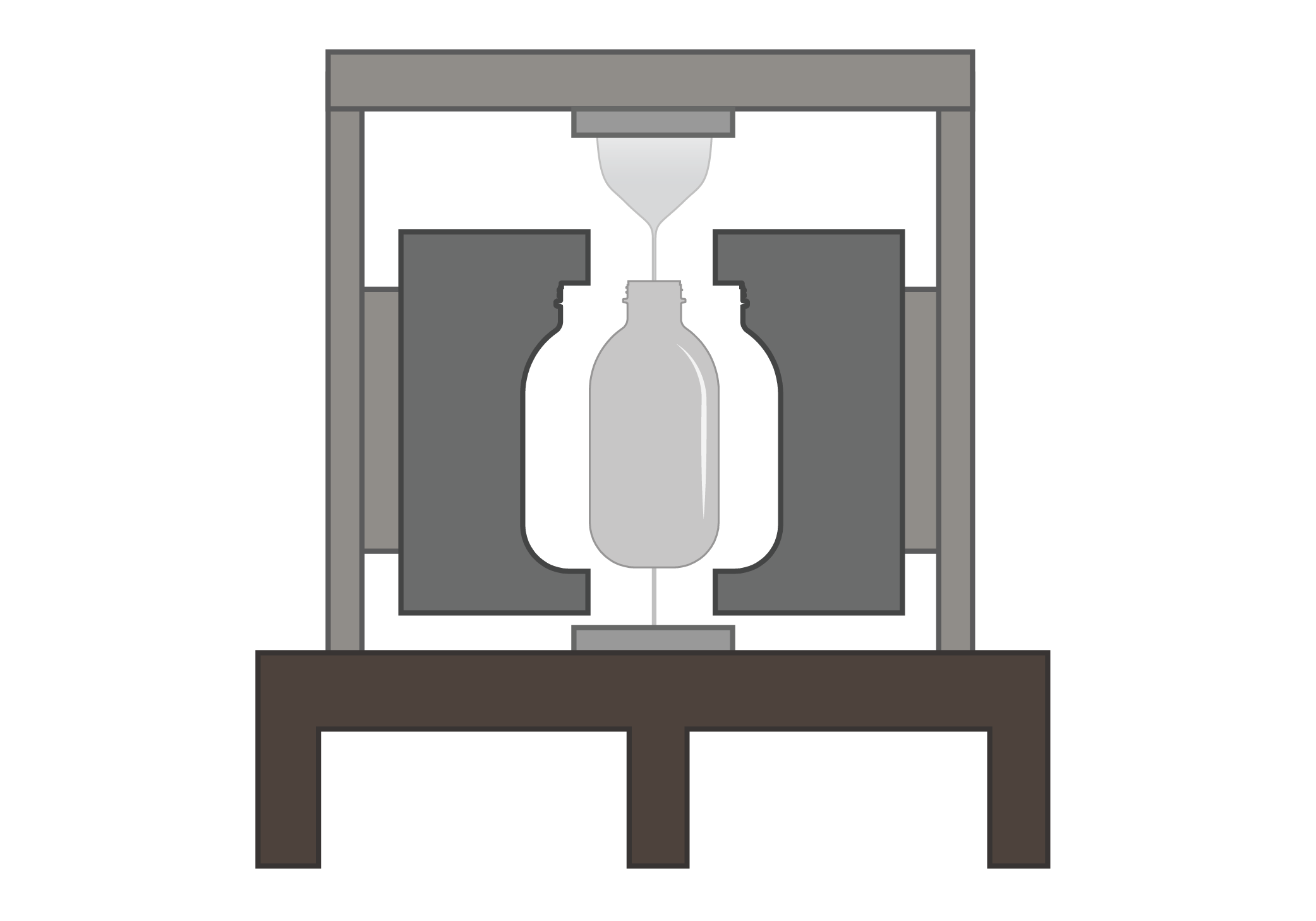

LINER

Even though we are known as experts of recycled fiber, just as much effort has been put into innovation around the types of polymers and plastics used in the liners.

Ecologic uses custom equipment to product thin, lightweight, collapsible liners that act as the perfect partner to the modled fiber shells. The liner holds and safeguards the product, the most important job for any packaging, and is fully recyclable at end-of-life as #1 PET.

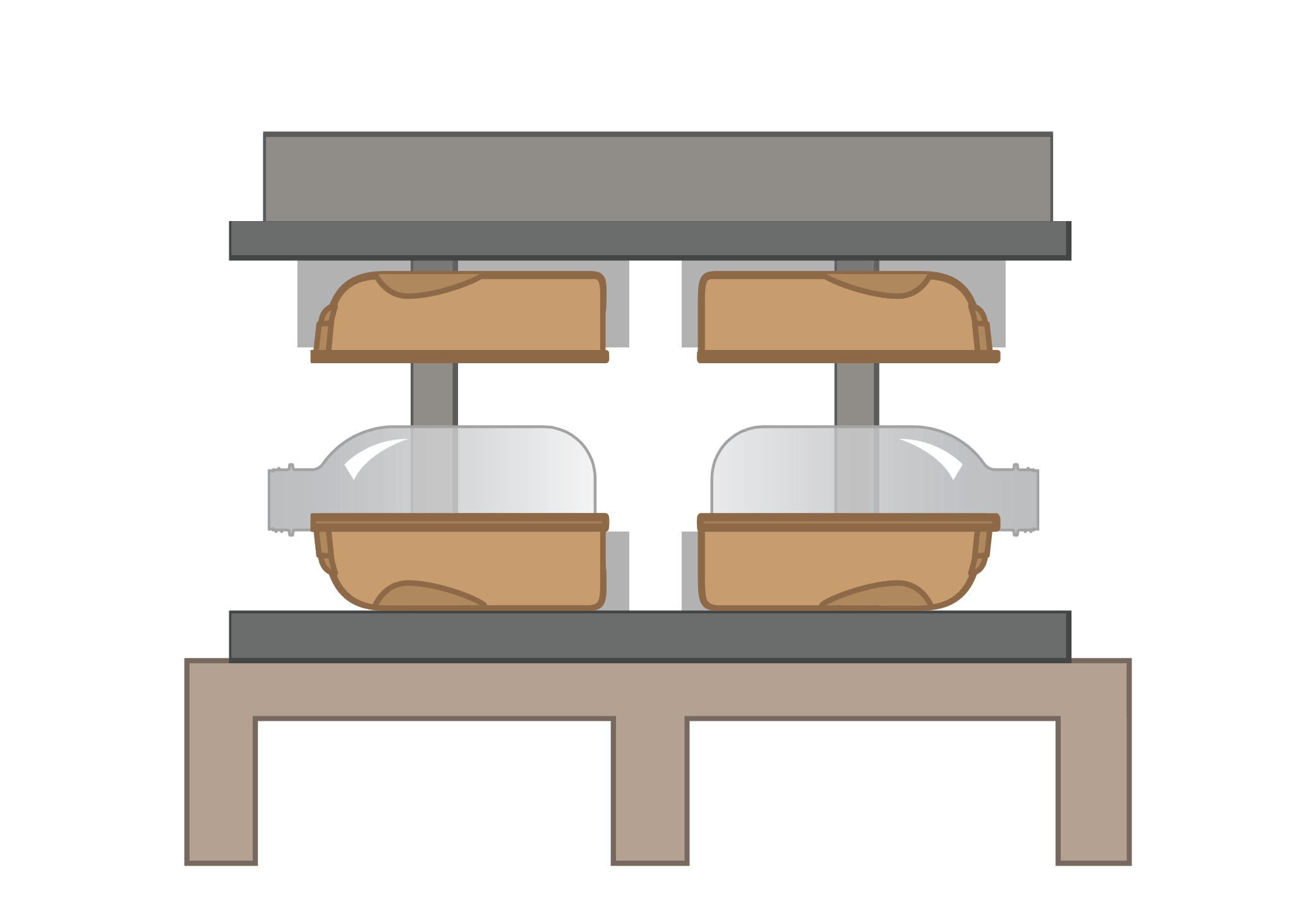

INTEGRATION

A critical step to producing an eco.bottle is assembly. Molded fiber shells and thin plastic liners are sent through a proprietary integration machine that locks the components together, forming a functional and sturdy container ready for filling and shipping.

Our eco.bottles have been rigorously performance tested to meet moisture resistance, top load, torque, and ISTA requirements.

MEASURING OUR IMPACT

LESS PLASTIC

LESS SOLID WASTE

Good for people, planet, and profit, the eco.bottle delivers measurable benefits vs. traditional packaging.